Welcome to Hebi Xinda Instrument Co., Ltd.!

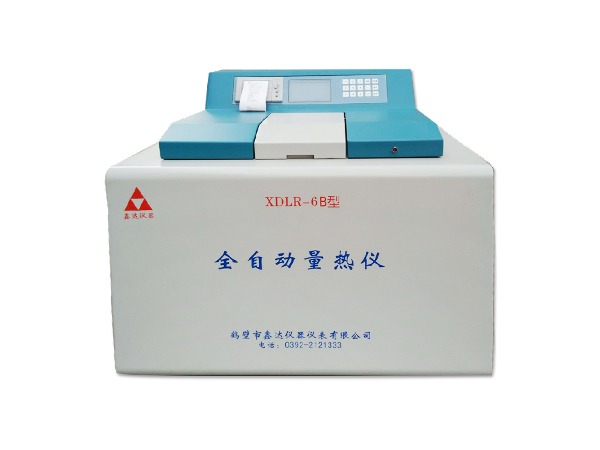

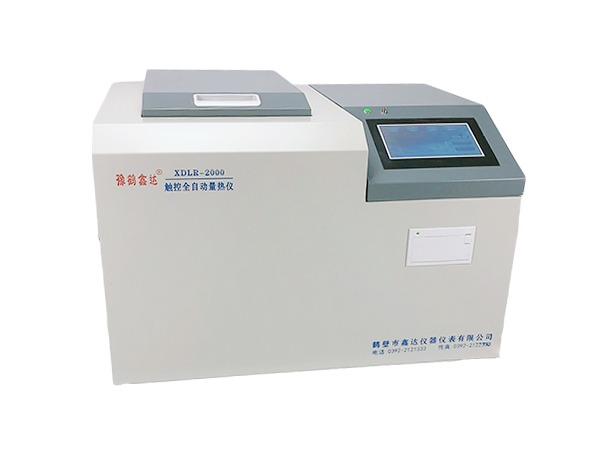

XDLR-Q500 Single Control Calorimeter

PRODUCT PARAMETERS

- Single-Control System

- Exceptional Measurement Accuracy

- Intuitive Operation

- Robust Data Analysis Software

- Flexible Temperature Range

Description

The XDLR-Q500 Calorimeter, a sophisticated single-control system designed for exceptional thermal analysis. Perfect for scientists, researchers, and engineers in various fields, the XDLR-Q500 offers superior performance and reliability. Explore the comprehensive features and specifications of the XDLR-Q500 below.

XDLR-Q500 Single Control Calorimeter Technical Parameters

| Temperature measurement range | 5~40℃ |

| Temperature resolution | 0.0001℃ |

| Test accuracy | ≤0.15% |

| Accuracy | Better than national standards |

| Test time | Conventional method: ≤16min Fast method: ≤11min |

| Heat capacity fluctuation | ≤0.20% within one year |

| Water level | Visible water level |

| Placement method | Vertical, horizontal |

| Quantitative method | Measuring cup quantitative |

| Power | <1kW |

| Dimensions | 570mm (length) × 550 mm (width) × 530 mm (height) |

| Power supply voltage | AC220V±22V, 50Hz±1Hz |

| Weight | 68kg |

XDLR-Q500 Single Control Calorimeter Features Of The Instrument

More convenient operation:High degree of automation, automatic and accurate water volume in the inner cylinder; automatic adjustment and tracking of system temperature; less manual operation content, reducing human errors and labor intensity, and improving work efficiency.

Fast experiment:Unique three-head thread and corrosion-resistant oxygen bomb (can burn biomass fuel), short test time.

Good stability:The quantitative water cup ensures the accurate and stable water volume in the inner cylinder, ensures the consistency of each measurement result, and has a built-in automatic refrigeration cycle control device. Different inner and outer cylinder temperature control methods can be selected according to needs, with a built-in filtration system to prevent system blockage, long-term stability of instrument heat capacity, and heat capacity change ≤0.2%.

Powerful software system:Experiment login permission management, automatic recording of experimental process, traceability. Sample code and weight information are automatically transmitted; test results are backed up and uploaded; anti-tampering experimental data, suitable for fuel control system. It has a self-diagnosis function and is easy to maintain.

Reserved standard interface: convenient for connection with the laboratory control system.

XDLR-Q500 Single Control Calorimeter Adopting standards

GB/T 213-2008 “Method for determination of calorific value of coal”

GB/T 384-1981 “Method for determination of calorific value of petroleum products”

GB/T 30727-2014 “Method for determination of calorific value of solid biomass fuel”

GB/T14402-2007 “Determination of combustion calorific value of combustion performance of building materials and products”

GB/T 30991-2014 “General technical conditions for intelligent oxygen bomb calorimeter”

JC/T 1005-2006 “Method for determination of calorific value of cement black raw meal”

JJG 672-2018 “Verification procedures for oxygen bomb calorimeter”

ASTM D5865-13 “Method for determination of calorific value of coal and coke”

ISO 1928:2009 “Determination of calorific value of solid mineral fuel”

CEN/TS 14918 “Method for determination of calorific value of solid biofuels”

BS EN 15400-2011 “Solid recovered fuels – calorific value test”

IS:1350-1970 “Method for determination of coal and coke”

XDLR-Q500 Single Control Calorimeter Application

It is suitable for measuring the calorific value of coal, coke, petroleum, food, cement raw materials, biofuels and other solid or liquid combustibles in industries such as electricity, coal, environmental protection, energy conservation, petrochemicals, metallurgy, cement, papermaking, food, geological exploration, scientific research institutions, etc.

FAQs

Our equipment is in line with national standards

We have complete video tutorials and you can learn from them one-on-one.

We provide a variety of analytical instruments including calorimeters, fast intelligent sulfur analyzers, muffle furnaces, microcomputer time and temperature program controllers, ignition point testers, explosion point testers, ash melting point testers, hydrocarbon element analyzers, gelatin layer testers, sample makers, crushers, combined sample makers, drying oven series, adhesion index testers, etc.

We cooperate with many logistics companies to choose the appropriate delivery method according to the characteristics of the goods and customer needs.

Usually shipped by sea and air.

Our standard products are manufactured to uniform designs and specifications and currently do not support customization.

If you have special needs, we recommend that you consider our existing product lines, as one of our products may be able to meet your needs.