Welcome to Hebi Xinda Instrument Co., Ltd.!

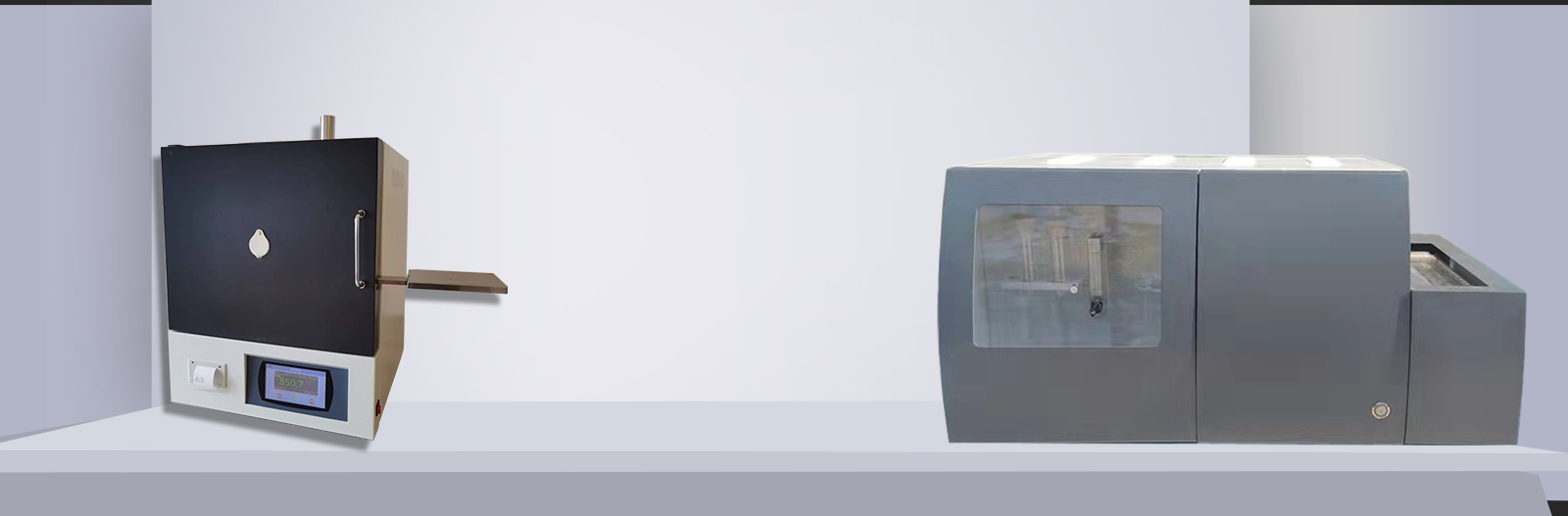

XDHR-350 Ash Fusibility Tester

PRODUCT PARAMETERS

- 1. High-resolution imaging: Equipped with a high-resolution camera, it can capture detailed images of ash samples during the melting process.

- 2. Precise temperature control: It features a programmable temperature controller that ensures accurate and consistent heating rates. The temperature range can be set from room temperature to 1600°C, providing flexibility for a variety of testing requirements.

- 3. Sturdy construction: Made of high-quality materials, it is durable and can be used for a long time. Its solid construction ensures stable and reliable operation even in harsh laboratory environments.

Description

XDHR-350 Ash Fusibility Tester is a sophisticated ash fusion tester designed to accurately determine the melting behavior of ash samples under controlled heating conditions. This equipment is essential for industries that require the characterization of ash properties for quality control, research, and environmental compliance. With its cutting-edge technology and user-friendly design, the XDHR-350 is the preferred choice for international laboratories and professionals.

XDHR-350 Ash Fusibility Tester Technical parameters

| Test method | oxidizing atmosphere, weak reducing atmosphere (carbon sealing method, ventilation method) |

| Maximum working temperature | 1,600ºC |

| emperature measurement accuracy | ±1ºC |

| Image storage interval | 1 frame/2ºC (temperature interval can be set) |

| Number of samples | 1~5 |

| Dimensions (length×width×height mm) | 660×530×1050 |

| Weight | 120kg |

| Heating speed: Before 900ºC | 15~30ºC/minute (settable) after 900ºC: 5~10ºC/minute (settable) |

| Precision and compliance standards | GB/T219-2008 |

| Accuracy | T1≤40ºC T2~T4≤30ºC |

| Power supply | 220±20VAC 50±1Hz |

| Power | ≤5kW |

XDHR-350 Ash Fusibility Tester Performance Features

1.High system accuracy:Imported CCD digital camera, automatic aperture lens and control system are used to automatically complete the coal ash fusibility test.

2.Long service life. Image reflection technology and independent camera cooling structure are used to reduce the impact of thermal radiation on the camera system and extend its life.

3.High degree of automation. The X+Z axis dual platform delivers the sample to the laboratory technician to ensure that the sample is not tilted and avoid the problem of inaccurate positioning caused by manual sample delivery.

4.Real-time monitoring of the entire test process. Using high-intelligence image processing and image recognition technology, it can accurately and automatically identify, save and print the characteristic temperatures of the measured sample such as DT (deformation temperature), ST (softening temperature), HT (hemisphere temperature), FT (flow temperature).

5.Reproducible test process. Real-time images can be automatically saved according to the user-defined heating interval. After the test is completed, the test process can be reproduced for further analysis and processing. According to the playback image, the four characteristic temperatures automatically determined by the computer can be manually determined again.

6.Convenient manual observation. While the computer automatically performs video monitoring, it can also conveniently view the actual ash cone status in the current furnace through a specially designed manual observation device.

7.Temperature measurement accuracy: B-type thermocouple is used to collect temperature, which has a higher temperature and is close to the real temperature. It can be heated to 1600ºC.

8.Thermocouple is built-in, and the thermocouple is inserted into the center of the ash cone support plate, so the temperature collection is closer to the real temperature.

9.Furnace environment treatment: One-piece furnace tube is used, and the inside and outside of the furnace are double-sealed. The cavity is small, and the amount of gas material used is small. (Only about 1g of activated carbon is needed to ensure the weak reducing atmosphere conditions in the furnace).

10.Lens dustproof technology. The furnace mouth is specially designed to ensure sealing, and the lens is clean to the greatest extent, which can ensure that it does not need to be wiped within 30 times.

11.Front camera, spiral macro six-degree-of-freedom focusing. Debugging is convenient and fast. After the first debugging, a single person can adjust the camera within 2 minutes for debugging again.

12.Adopt T1700 high-temperature silicon molybdenum rod heating, special silicon molybdenum rod clamp, which can work for a long time above 1500.

13.The ash cone support plate design with grooves does not affect the judgment of other samples after the ash cone flows.

XDHR-350 Ash Fusibility Tester Product Applications:

Coal and coke industry, power generation, cement and lime production, metallurgy and mining operations, waste incineration and environmental monitoring, research institutions and universities, quality control laboratories, etc.

FAQs

Our equipment is in line with national standards

We have complete video tutorials and you can learn from them one-on-one.

We provide a variety of analytical instruments including calorimeters, fast intelligent sulfur analyzers, muffle furnaces, microcomputer time and temperature program controllers, ignition point testers, explosion point testers, ash melting point testers, hydrocarbon element analyzers, gelatin layer testers, sample makers, crushers, combined sample makers, drying oven series, adhesion index testers, etc.

We cooperate with many logistics companies to choose the appropriate delivery method according to the characteristics of the goods and customer needs.

Usually shipped by sea and air.

Our standard products are manufactured to uniform designs and specifications and currently do not support customization.

If you have special needs, we recommend that you consider our existing product lines, as one of our products may be able to meet your needs.