Welcome to Hebi Xinda Instrument Co., Ltd.!

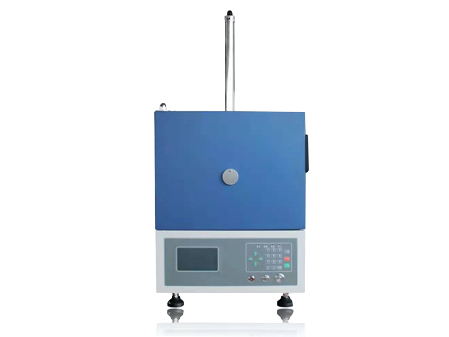

Muffle Furnace

PRODUCT PARAMETERS

- High-Performance Heating System

- Spacious Chamber Design

- Robust and Durable Construction

- User-Friendly Operation

- Comprehensive Safety Features

- Ease of Maintenance

Description

Elevate your lab’s heat treatment capabilities.

Our muffle furnace is an advanced heating system designed to revolutionize high temperature applications in research and industrial laboratories around the world. Engineered to combine cutting-edge technology, craftsmanship, and user-centric design, this furnace delivers unmatched performance and reliability. Embrace the future of heat treatment with our muffle furnaces.

Muffle Furnace Technical Parameters

| Operating temperature | 0~1000℃ |

| Rated power | 4kW |

| Furnace size (mm) | 325×200×125 |

| Overall dimensions (mm) | 560×640×760 |

| Machine weight | 68kg |

Muffle Furnace Performance Features

Adopt new insulation materials, light weight, good insulation effect, fast heating speed.

The overall design is reasonable, equipped with a controllable chimney, easy to operate.

Beautiful shape, exquisite workmanship, strong and durable, not easy to deform.

Easy to replace, install and maintain the heating wire.

Stainless steel shell design.

Muffle Furnace Application Range

Muffle furnace is suitable for industrial analysis in industries and sectors such as coal, electricity, chemical industry, metallurgy, cement, geological exploration, medicine, scientific research, etc. It can be used with a microcomputer time and temperature program controller to measure ash content, volatile matter, Roga index, bonding index, and thermal stability of coal. It can also be used for sintering and heat treatment processes.

FAQs

Our equipment is in line with national standards

We have complete video tutorials and you can learn from them one-on-one.

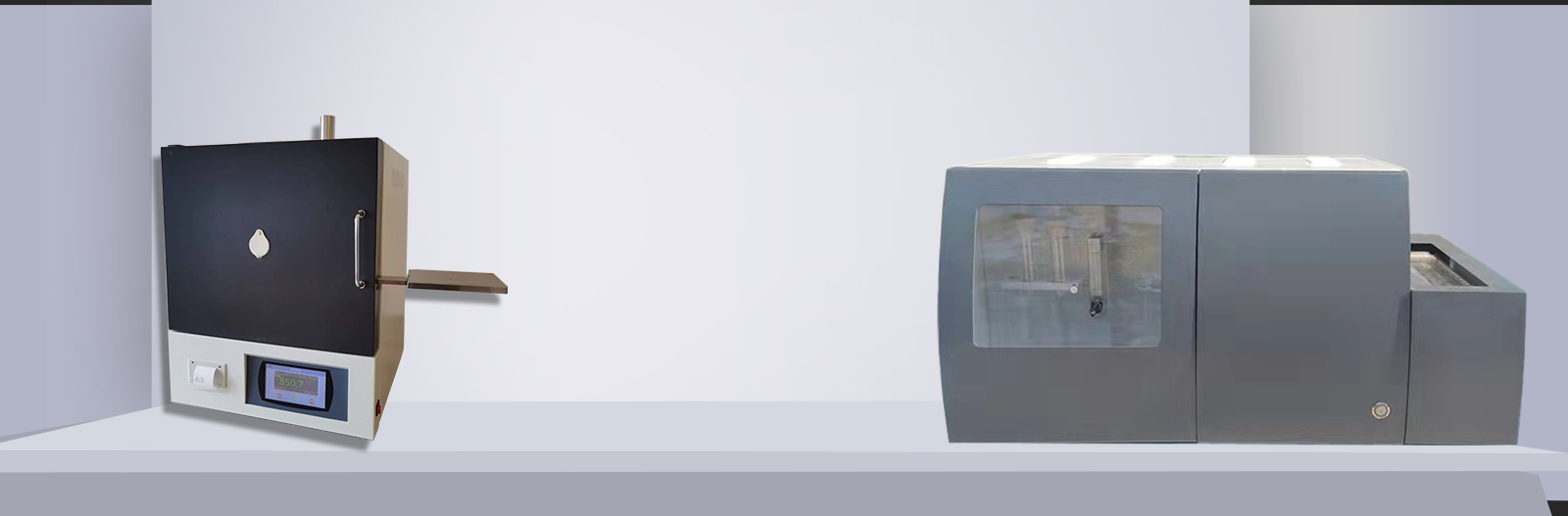

We provide a variety of analytical instruments including calorimeters, fast intelligent sulfur analyzers, muffle furnaces, microcomputer time and temperature program controllers, ignition point testers, explosion point testers, ash melting point testers, hydrocarbon element analyzers, gelatin layer testers, sample makers, crushers, combined sample makers, drying oven series, adhesion index testers, etc.

We cooperate with many logistics companies to choose the appropriate delivery method according to the characteristics of the goods and customer needs.

Usually shipped by sea and air.

Our standard products are manufactured to uniform designs and specifications and currently do not support customization.

If you have special needs, we recommend that you consider our existing product lines, as one of our products may be able to meet your needs.