Welcome to Hebi Xinda Instrument Co., Ltd.!

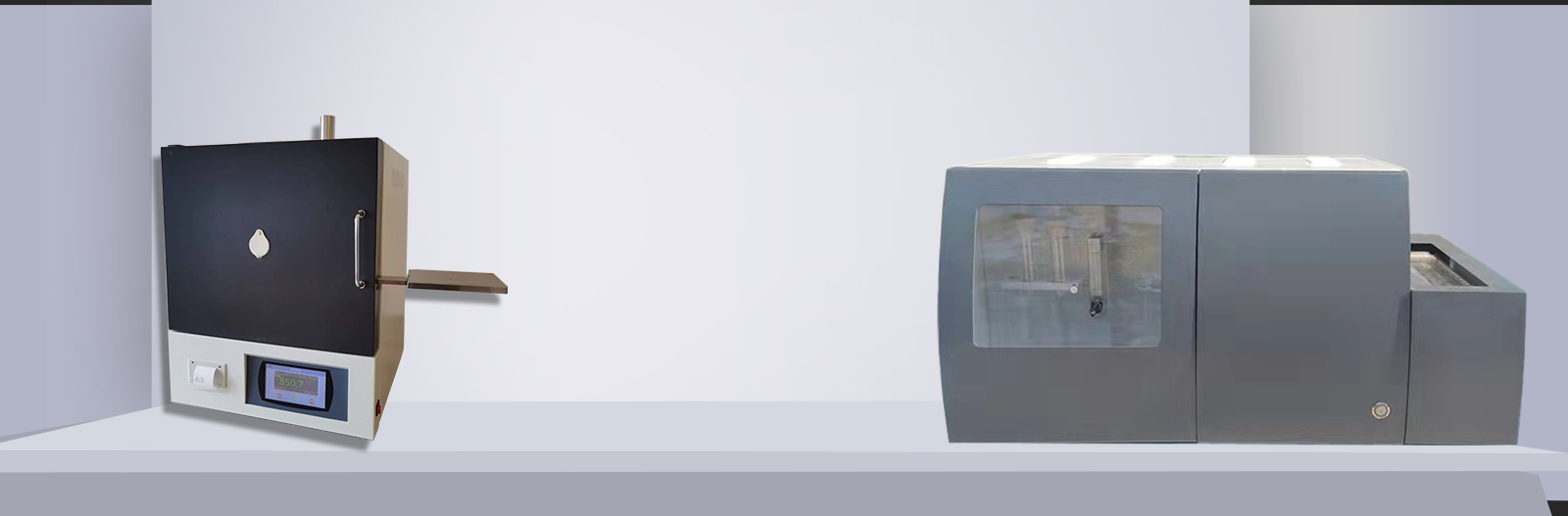

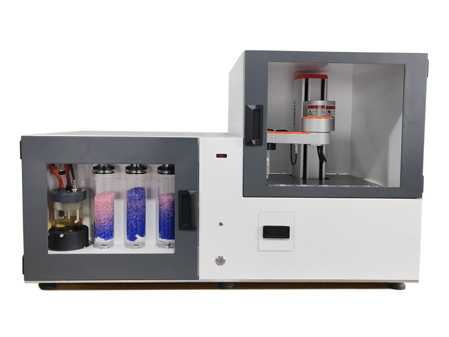

XDS220 Robotic Coulometric Sulfur Analyzer

PRODUCT PARAMETERS

- Fully Automated Robotic System

- Coulometric Measurement Technique

- High Precision and Repeatability

- User-Friendly Software Interface

- Low Maintenance and Longevity

- Comprehensive Data Analysis and Reporting

Description

This XDS220, a state-of-the-art robotic coulometric sulfur analyzer designed to deliver precise and automated sulfur measurements. This innovative instrument combines advanced robotics with the reliability of coulometric analysis, offering a seamless solution for laboratories and industries that demand high-quality sulfur testing with minimal operator intervention.

XDS220 Robotic Coulometric Sulfur Analyzer Technical Parameters

| Number of samples (pieces/time) | 25 samples (unlimited samples can be added) |

| Sulfur measurement range | 0.01%~40% |

| Resolution | 0.001% |

| Sample weight (mg) | 45~55 (coal), 80~100 (oil) |

| Minimum test time for a single sample (min) | 3, 5min/sample |

| Working furnace temperature (℃) | 1150 (coal, coke), 920 (oil) |

| Temperature control accuracy (℃) | ±1 |

| Power (kw) | <3 |

| Weight (kg) | 60 |

| Dimensions (mm) | 1100x550x675 |

XDS220 Robotic Coulometric Sulfur Analyzer Features

1、The advanced high-precision robot gripper is used, and the multiple shock-absorbing sample delivery mechanism is used to ensure the stability and reliability of sample delivery, and the sample will not fall or get stuck. The operator only needs to prepare the sample (up to 25 samples for the first time and unlimited samples can be added) and put it on the sample tray, and the instrument will automatically complete the analysis.

2、Automatic sample delivery, experiment, sample output, and sample loss are realized, which can be unattended, and samples can be added or replaced at any time during the experiment.

3、Tungsten trioxide can be added automatically and quantitatively, and the distribution is uniform.

4、The digital flow meter is used, and the gas flow can be displayed in real time.

5、The new DSP technology and hardware integration circuit are used, which has strong real-time and reliability, and the software upgrade is convenient.

6、The large-electrode electrolytic cell is used to ensure the repeatability and accuracy of the test results.

7、Self-detection can be performed when the machine is turned on, fault information can be displayed, and maintenance suggestions can be provided.

8、Convenient liquid discharge control is convenient for cleaning the electrolytic cell and replacing the electrolyte.

9、Large-capacity drying tube reduces the frequency of desiccant replacement.

10、Imported air pumps are used, with stable flow and low noise.

11、Can be connected to the Internet and external electronic balance.

12、Horizontal imported furnace and national standard porcelain boat are used, which fully meet the national standard requirements.

13、The database can be opened to third parties to access the laboratory management system to achieve real-time backup and upload of test results.

XDS220 Robotic Coulometric Sulfur Analyzer Applications

The XDS220 Robotic Coulometric Sulfur Analyzer is ideal for a broad spectrum of applications, including quality control in the oil refining, petrochemical, and environmental sectors. It is specifically designed for accurate sulfur analysis in fuels, oils, and other organic materials.

XDS220 Robotic Coulometric Sulfur Analyzer Adopts The Following Standards

GB/T 214-2007 “Determination of total sulfur in coal”

Replaces GB/T 28732-2012 “Determination of total sulfur in solid biomass fuels”

Replaces ISO 16994-2015 “Determination of sulfur and chlorine in solid biofuels”

FAQs

Our equipment is in line with national standards

We have complete video tutorials and you can learn from them one-on-one.

We provide a variety of analytical instruments including calorimeters, fast intelligent sulfur analyzers, muffle furnaces, microcomputer time and temperature program controllers, ignition point testers, explosion point testers, ash melting point testers, hydrocarbon element analyzers, gelatin layer testers, sample makers, crushers, combined sample makers, drying oven series, adhesion index testers, etc.

We cooperate with many logistics companies to choose the appropriate delivery method according to the characteristics of the goods and customer needs.

Usually shipped by sea and air.

Our standard products are manufactured to uniform designs and specifications and currently do not support customization.

If you have special needs, we recommend that you consider our existing product lines, as one of our products may be able to meet your needs.